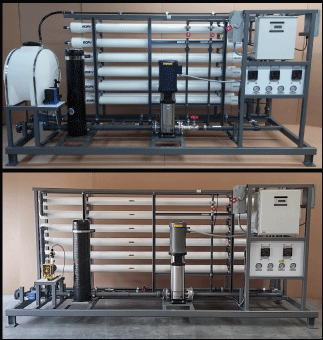

REVERSE OSMOSIS SYSTEM

Model: FMH (Frame Mount Horizontal)

12,000 to 41,400+ GPD

STANDARD FEATURES

- Reverse Osmosis Membrane

- Powder-coated steel frame

- Stainless steel multi-stage pump

- 80″ membrane vessel

- SCH 80 PVC manifolding

- Feed/concentrate pressure gauges

- Liquid-tight wire shrouding

- Motorized inlet ball valve

- Adjstbl. s.s. concentrate valve

- Product/Concentrate/Recycle sensor powered flow meters

- product sampling valves per vessel

- Two 20″ 5 micron pre-filters

- Pre and post-filter gauges

- Victaulic couplings

- Stainless steel throttling switch

- Fused main disconnect switch

- Low voltage dual-level product switches

- Optimum performance membrane array

STANDARD ELECTRICAL CONTROLS:

- Menu system with Keypad

- Product and Feed water TDS monitoring

- Manual start override on tank full condition

- Feed water temperature

- Low voltage level control

- Hour Meter

- Audible low pressure alarm

- Low pressure switch

- System ON/OFF

- Time delay start

- Low pressure bypass delay

OPTIONS:

- Nanofiltration Membrane

- Automatic flush

- Pre-treatment lock-out

- Permeate purge

- Antiscalant pump w/tank

- Hi-pressure cut-off

- Product diversion

- Stainless Steel multiple cartridge filter housing to be used for sediment removal

- 3phase motor w/IEC motor contactor

- 50hz electrical

| MODEL | GPD | MEMBRANE 4″X40″ QTY |

OPERATING PRESSURE |

|---|---|---|---|

| FMH4-2 FMH4-2S |

12,000+ 13,800+ |

8 8 |

200psi 150psi |

| FMH6-2 FMH6-2S |

18,000+ 20,700+ |

12 12 |

200psi 150psi |

| FMH8-2 FMH8-2S |

23,700+ 27,600+ |

16 16 |

200psi 150psi |

| FMH10-2 FMH10-2S |

29,900+ 34,500+ |

20 20 |

200psi 150psi |

| FMH12-2 FMH12-2S |

35,000+ 41,400+ |

24 24 |

200psi 150psi |

FEED WATER PARAMETERS:

- Temperature: 85° F maximum

- Pressure: 40 – 80 psi maximum

- TDS: 2000-5000 ppm maximum (Consult Dealer for specific model)

- Iron tolerance: 0.5 ppm maximum

- Hydrogen sulfide: must be removed

- Silica tolerance: can not be higher than 100 ppm in the concentrate stream.

(Antiscalant should be considered for any levels over 75 ppm) - Turbidity: should be removed

- Hardness: must be removed

OPERATING PARAMETERS:

- Operating pressure: 150 – 200 psi maximum

- Water recovery: up to 70% and is field adjusted by customer.

(It is not recommended that the recovery be set higher than 70%) - pH range: 3 – 11

- Flow rates are determined by the membrane mfg.’s. testing criteria of 1500 ppm Nacl solution, 77°F water temperature, 225 psi at 10-15% recovery. Typical membrane salt rejection is 95-99%

*Actual flow rates may vary depending on the pre-treatment used, water conditions, feed water temperature and applied pressure, etc.