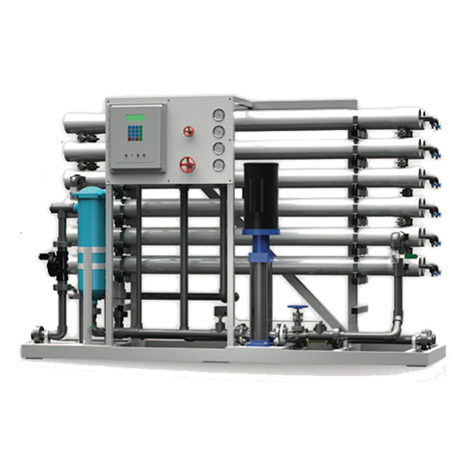

Axeon M1-Series

M1-Series Reverse Osmosis Systems are designed for overall superior performance, high recovery rates, minimal energy consumption and offer great savings with low maintenance and operation costs.

M1-Series Reverse Osmosis Systems feature a new, innovative and expandable design which utilizes fewer fittings and connections. These systems feature only the highest quality components, including a programmable computer controller with many built-in standard features, a stainless steel booster pump for high

performance and corrosion resistance, extra low energy membranes and fiberglass membrane housings for enhanced performance and durability.

M1-Series Reverse Osmosis Systems have been engineered for capacities ranging from 12000 – 36000 gallons per day.

Benefits

- Fully Equipped and Customizable

- Expandable and Skid Mounted

- Components Easily Accessible

- Pre-Plumbed, Wired and Assembled

- Individually Tested and Preserved

- Low Operation and Maintenance Costs

- Easy Maintenance and Servicing

- CE Compliant†

- 1-Year Limited Warranty

- Made in the U.S.A.

STANDARD FEATURES

Models – M1-4240, M1-6240, M1-8240

- S150 Computer Controller N LCD Backlit Display

- Pre-Treatment Lockout

- Tank Level Input

- Low Pressure Monitoring and Alarm

- Dual TDS Monitoring

- Expander Board

- Hour Meter

- Feed Flush

Models – M1-10240, M1-12240

- Rotrol II Computer Controller

- LCD Backlit Display

- Pre-Treatment Lockout

- Tank Level Input

- LED Low Pressure Monitoring and Alarm

- Hour Meter

- Dual TDS Monitoring

- Expander Board

- Feed Flush

- Digital Flow Meters

- Concentrate Recycle with Digital Flow Meter

- AXEON Permeate and Concentrate Flow Meters

- AXEON Concentrate Recycle Flow Meter

- Stainless Steel Concentrate Globe Valve

- AXEON Pre-Filter 0-100 psi Panel Mounted Glycerin Filled Gauges

- AXEON Pump Discharge and Concentrate 0-300 psi Panel Mounted Glycerin Filled Gauges

- FSI® Bag Filter Housing with Stainless Steel Stand

- FSI® 5 Micron Filter Bag

- AXEON HF4 Extra Low Energy Membrane Elements

- Fiberglass Membrane Housings – 450 psi

- Goulds® Vertical Multi-Stage Stainless Steel Booster Pump

- Feed Solenoid Valve with Manual Bypass

- Feed Low Pressure Switch

- Clean-In-Place (CIP) Ports

- Victaulic® Style Fittings

- Permeate Sample Ports

- White Powder Coated Aluminum Frame

- Caster Wheels

- Wooden Crate

Options and Upgrades

- S150 Expander Board***

- S150 Dual TDS Board***

- Rotroll ll Controller Feed TDS Sensor

- Variable Frequency Drive††

- AXEON HF5 Ultra Low Energy Membrane Elements

- AXEON NF3 Nanofiltration Membrane Elements

- AXEON NF4 Nanofiltration Membrane Elements

- Filmtec® LCLE Membrane Elements

- Filmtec® LCHR Membrane Elements

- Hanna® BL 981411 pH Meter***

- Hanna® BL 982411 ORP Meter***

- Rotroll ll pH Monitoring

- Rotroll ll ORP Monitoring

- Chemical Pump Outlet

- Blending Valve

- High Pressure Tank Switch

- Pump Pressure Relief Valve†

- Permeate Divert Valve

†† Standard for all 50Hz Systems

*** Only available on the following models: M1-4240, M1-6240, M1-8240

Array Specifications

| Model |

Vessel Array |

Vessel Size |

Vessel Quantity |

Membrane Size |

Membrane Quantity |

| M1-4240 |

1:1:1:1 |

4080 |

4 |

4040 |

8 |

| M1-6240 |

2:2:1:1 |

4080 |

6 |

4040 |

12 |

| M1-8240 |

3:3:2 |

4080 |

8 |

4040 |

16 |

| M1-10240 |

3:3:2:2 |

4080 |

10 |

4040 |

20 |

| M1-12240 |

3:3:2:2:2 |

4080 |

12 |

4040 |

24 |

| Models |

M1-4240 |

M1-6240 |

M1-8240 |

M1-10240 |

M1-12240 |

| Design |

| Configuration |

Single Pass |

Single Pass |

Single Pass |

Single Pass |

Single Pass |

| Feed Water Source*** |

TDS<2,000 ppm |

TDS<2,000 ppm |

TDS<2,000 ppm |

TDS<2,000 ppm |

TDS<2,000 ppm |

| Standard Recovery Rate |

50–75% |

50–75% |

50–75% |

50–75% |

60–75% |

| Rejection and Flow Rates |

| Nominal Salt Rejection % |

99 |

99 |

99 |

99 |

99 |

| Permeate Flow* gpm (lpm) |

8.3 (31.6) |

12.5 (47.3) |

16.7 (63.1) |

20.8 (78.9) |

25.0 (94.6) |

| Minimum Feed Flow gpm (lpm) |

11.3 (42.9) |

15.5 (58.7) |

22.7 (85.8) |

26.8 (101.6) |

31.0 (117.4) |

| Maximum Feed Flow gpm (lpm) |

48 (181.7) |

48 (181.7) |

48 (181.7) |

48 (181.7) |

48 (181.7) |

| Minimum Concentrate Flow gpm (lpm) with Recycle Based on 75% Recovery |

3.00 (11.36) |

4.17 (15.79) |

5.56 (21.04) |

6.95 (26.31) |

8.33 (31.53 |

| Connections |

| Feed inch |

1.5” FNPT |

1.5” FNPT |

1.5” FNPT |

1.5” FNPT |

1.5” FNPT |

| Permeate inch |

1” FNPT |

1” FNPT |

1” FNPT |

1.5” FNPT |

1.5” FNPT |

| Concentrate inch |

1” FNPT |

1” FNPT |

1” FNPT |

1.5” FNPT |

1.5” FNPT |

| CPI inch |

1” FNPT |

1” FNPT |

1” FNPT |

1” FNPT |

1” FNPT |

| Membranes |

| Membrane(s) Per Vessel |

2 |

2 |

2 |

2 |

2 |

| Membrane Quantity |

8 |

12 |

16 |

20 |

24 |

| Membrane Size |

4040 |

4040 |

4040 |

4040 |

4040 |

| Vessels |

| Vessel Array |

1:1:1:1 |

2:2:1:1 |

3:03:02 |

3:3:2:2 |

3:3:2:2:2 |

| Vessel Quantity |

4 |

6 |

8 |

10 |

12 |

| Pumps |

| Pump Type |

Multi-Stage |

Multi-Stage |

Multi-Stage |

Multi-Stage |

Multi-Stage |

| Motor HP (kw) |

3 |

3 |

5 |

7.5 |

7.5 |

| RPM @ 60 Hz |

3450 |

3450 |

3450 |

3450 |

3450 |

| RPM @ 50 Hz |

VFD at 60Hz |

VFD at 60Hz |

VFD at 60Hz |

VFD at 60Hz |

VFD at 60Hz |

| Electrical |

| Standard Voltage |

220V, 60Hz, 1Ph, 14.6A |

220V, 60Hz, 1Ph, 14.6A |

220V, 60Hz, 3Ph, 13.6A |

220V, 60Hz, 3Ph, 19.2A |

220V, 60Hz, 3Ph, 19.2A |

| Voltage Options |

220V, 50Hz, 1Ph, 17.4A 220V, 50Hz, 3Ph, 10.6A 220V, 60Hz, 3 Ph, 9A 460V, 60Hz, 3 Ph, 5A |

220V, 50Hz, 1Ph, 17.4A 220V, 50Hz, 3Ph, 10.6A 220V, 60Hz, 3 Ph, 9A 460V, 60Hz, 3 Ph, 5A |

220V, 50Hz, 3Ph, 16.1A 460V, 60Hz, 3 Ph, 7A |

220V, 50Hz, 3Ph, 22.9A 460V, 60Hz, 3 Ph, 9.7A |

220V, 50Hz, 3Ph, 22.9A 460V, 60Hz, 3 Ph, 9.7A |

| Systems Dimensions ** |

| L x W x H inch (cm) |

31 x 100 x 64 (78 x 254 x 162) |

31 x 100 x 64 (78 x 254 x 162) |

31 x 100 x 64 (78 x 254 x 162) |

31 x 100 x 64 (78 x 254 x 162) |

31 x 100 x 64 (78 x 254 x 162) |

| Weight lb. (kg) |

1060 (481) |

1150 (520) |

1260 (572) |

1350 (612) |

1450 (658) |

* Product flow and recovery rates are based on equipment test parameters.

†† Standard for all 50 Hz Systems

** Does not include operating space requirements.

*** Treatment ability of the RO system is dependent on feed water quality. Performance projections must be run for each installation.

Operating Limits

- Maximum Feed Temperature °F (°C): 85 (29)

- Maximum Free Chlorine ppm: 0

- Minimum Feed Temperature °F (°C): 40 (4.4)

- Maximum TDS ppm: 2,000

- Maximum Ambient Temperature °F (°C): 120 (48.9)

- Maximum Hardness gpg: 0

- Minimum Ambient Temperature °F (°C): 40 (4.4)

- Maximum pH (Continuous): 11

- Maximum Feed Pressure psi (bar): 85 (5.9)

- Minimum pH (Continuous): 5

- Minimum Feed Pressure psi (bar): 45 (3.1)

- Maximum pH (Cleaning 30 Min.): 12

- Maximum Operating Pressure psi (bar): 200 (13.8)

- Minimum pH (Cleaning 30 Min.): 2

- Maximum SDI Rating SDI: < 3

- Maximum Turbidity NTU: 1

Test Parameters: 550 TDS Filtered (5 Micron), De-Chlorinated, Municipal Feed Water, 65 psi (4.5 bar) Feed Pressure, 100 psi (6.89 bar) Operating Pressure, 77 Degrees F (25 Degrees C), Recovery as stated, 7.0 pH. Data taken after 60 minutes of operation.

Low temperatures and high feed water TDS levels will significantly affect the system’s production capabilities. Computer projections should be run for individual applications which do not meet or exceed minimum and maximum operating limits.

Scale prevention measures must be taken to prolong membrane life.

Axeon TF-Series

AXEON TF-Series Reverse Osmosis Polyamide-Thin Film Composite Membranes

are recognized as one of the industry’s most reliable and highest performing membrane elements that deliver consistent quality and performance. Advanced manufacturing processes and utilization of the industry’s leading film technology allows these elements to deliver consistent results that equipment suppliers and water treatment dealers have come to rely on.

- 98% Nominal Salt Rejection

- Improved System Performance

- Superior Quality and Cost Savings

- Individually Vacuum Tested

- Made in the U.S.A.

This Membrane Element is Tested and Certified by NSF International against NSF/ANSI Standard 58 for material requirements only.

AXEON residential membranes operate as low as 50 psi and can yield up to 23% more water than competitor’s membranes at 65 psi.

AXEON TF-Series Residential Reverse Osmosis Polyamide-Thin Film Composite Membranes offer reliability, high performance and deliver consistent results for higher quality water. AXEON membrane elements will fit a standard 2” x 12” residential membrane housing and are shipped dry for an indefinite shelf life and easier handling. Membrane elements may also be ordered as individually wet tested.

Operating Limits

- Maximum Operating Temperature: 113°F (45°C)

- Maximum Operating Pressure: 150 psi (10 bar)

- Maximum Feed Flow Rate: 2 gpm (7.6 lpm)

- pH Range, Continuous Operation*: 2 – 11

- Maximum Feed Silt Density Index (SDI): 5

- Chlorine Tolerance: 0 ppm

*Maximum temperature for continuous operations above pH10 is 95° F (35°c)

Product Specification

| Part Number |

Description |

Applied Pressure psi (bar) |

Permeate Flow Rate gpd (lph) |

Nominal Rejection (%) |

| 200357 |

TF-1812-25 |

50 (3.44) |

25 (3.94) |

98.0 |

| 200358 |

TF–1812–35 |

50 (3.44) |

35 (5.52) |

98.0 |

| 200359 |

TF–1812–50 |

50 (3.44) |

50 (7.88) |

98.0 |

| 200360 |

TF–1812–75 |

50 (3.44) |

75 (11.83) |

98.0 |

| 200361 |

TF–1812–100 |

60 (4.13) |

100 (15.77) |

98.0 |

| 300362 |

TF–1812–150 |

65 (4.48) |

150 (23.66) |

98.0 |

DIMENSIONS INCH (MM)

| Description |

A |

B |

C |

D |

E |

| TF-1812-25 |

11.74 (298.2) |

10.00 (254) |

.86 (21.84) |

.88 (22.35) |

1.77 (45.08) |

| TF–1812–35 |

11.74 (298.2) |

10.00 (254) |

.86 (21.84) |

.88 (22.35) |

1.77 (45.08) |

| TF–1812–50 |

11.74 (298.2) |

10.00 (254) |

.86 (21.84) |

.88 (22.35) |

1.77 (45.08) |

| TF–1812–75 |

11.74 (298.2) |

10.00 (254) |

.86 (21.84) |

.88 (22.35) |

1.77 (45.08) |

| TF–1812–100 |

11.74 (298.2) |

10.00 (254) |

.86 (21.84) |

.88 (22.35) |

1.77 (45.08) |

| TF–1812–150 |

11.74 (298.2) |

10.00 (254) |

.86 (21.84) |

.88 (22.35) |

1.77 (45.08) |

Wet tested membrane elements must be kept sealed and moist when in storage. Drying out may occur and damage the membrane permanently. Prevent elements from freezing or being exposed to direct sunlight. Wet tested elements are vacuum sealed in a polyethylene oxygen barrier bag containing 1.0% sodium meta-bisulfite and then packaged in a cardboard box. Discard the permeate for the first twenty-four hours of operation.Do not use the first full tank of permeate for drinking or food preparation. The permeate flow (product water flow) varies with feed water temperature. Review a Temperature Correction Chart. For membrane warranty information, please contact manufacturer.

The manufacturer believes the information and data contained herein to be accurate and useful. The information and data are offered in good faith, but without guarantee, as conditions and methods of use of products are beyond the manufacturer’s control. The manufacturer assumes no liability for results obtained or damages incurred through the application of the presented information and data. It is the user’s responsibility to determine the appropriateness of the products for the user’s specific end uses.

WM (Wall Mount)

REVERSE OSMOSIS SYSTEM

Model: WM (Wall Mount)

1,800 to 6,500+ GPD

STANDARD FEATURES

- Reverse Osmosis Membrane

- Powder-coated steel frame

- Stainless steel multi-stage pump

- Stainless steel membrane vessel

- High-pressure nylon tubing

- Liquid-filled high pressure gauge

- Inlet/Outlet pre-filter gauges

- Liquid-tight wire shrouding

- Feed water inlet solenoid valve

- Adjstbl. waste & recycle s.s. needle valves

- Product / waste flow meters

- 10″ 5 micron BB pre-filter

- High-pressure brass comp. fittings

STANDARD ELECTRICAL CONTROLS:

- 4-line LCD display

- Keypad

- Menu system

- Temperature display

- TDS monitor with probe

- Tank full

- Low pressure

- Hour meter

- Time delay start

- System ON / OFF

- Dual-level control

- Fully-fused

OPTIONS:

- Low energy, super-high flow membrane

(Ideal for low water temp applications)

- Nanofiltraion Membrane

(Removes 98% hardness, up to 85% TDS, high recovery rate)

- Blending valve

- Throttle valve

- Recycle flow meter

- 20″ BB pre-filter

- 3phase motor w/IEC

- 50hz Motor

- Auto hourly flush

- Feed water TDS monitor

- Pre-treatment lock-out

- Product diversion

- Permeate purge

| Model |

GPD |

MEMBRANE |

RECOVERY

RATE |

PIPING

inlet waste product |

DIMENSIONS

weight lbs. |

| SIZE |

QTY |

TYPE |

WM140

WM140S |

1,800-2,000

2,500-2,800 |

4″X40″

4″X40″ |

1

1 |

Standard

Low-energy |

50-70% |

3/4″ 1/2″ 1/2″

FPT FPT FPT |

36″x15″58″H

130 lbs |

WM240

WM240S |

3,600-4,000

4,500-5,200 |

4″X40″

4″X40″ |

2

2 |

Standard

Low-enegry |

50-70% |

3/4″ 1/2″ 1/2″

FPT FPT FPT |

36″x15″x58″H

156 lbs |

WM340

WM340S |

4,800-5,600

5,500-6,500 |

4″X40″

4″X40″ |

3

3 |

Standard

Low-enegry |

50-70% |

3/4″ 1/2″ 1/2″

FPT FPT FPT |

36″x15″x58″H

184 lbs |

FEED WATER PARAMETERS:

- Temperature: 85° F maximum

- Pressure: 40 – 80 psi maximum

- TDS: 2000ppm maximum (Consult Dealer for specific model)

- Iron tolerance: 0.5 ppm maximum

- Hydrogen sulfide: must be removed

- Silica tolerance: can not be higher than 100 ppm in the concentrate stream.

(Antiscalant should be considered for any levels over 75 ppm)

- Turbidity: should be removed

- Hardness: must be removed

OPERATING PARAMETERS:

- Operating pressure: 150 – 200 psi maximum

- Water recovery: up to 70% and is field adjusted by customer.

(It is not recommended that the recovery be set higher than 70%)

- pH range: 3 – 11

- Flow rates are determined by the membrane mfg.’s. testing criteria of 1500 ppm Nacl solution, 77°F water temperature, 225 psi at 10-15% recovery. Typical membrane salt rejection is 95-99%

*Actual flow rates may vary depending on the pre-treatment used, water conditions, feed water temperature and applied pressure, etc.

STG (Skid-To-GO)

REVERSE OSMOSIS SYSTEM

Model: STG (Skid-To-Go)

800 to 14,400+ GPD

STANDARD FEATURES

- Reverse Osmosis Membrane

- Twin tank water softener w/auto backwash

- Carbon filter w/auto backwash

- 24gpm ultraviolet water sterilizer, s.s.

- 1hp s.s. repressurization

- TDS blending valve

- Powder-coated steel frame

- Stainless steel multi-stage pump

- Stainless steel membrane vessel

- High-pressure nylon tubing

- Liquid-filled high pressure gauge

- Inlet/Outlet pre-filter gauges

- Liquid-tight wire shrouding

- Feed water inlet solenoid valve

- Adjstbl. waste & recycle s.s. needle valves

- Product / waste flow meters

- 10″ 5 micron BB pre-filter

- High-pressure brass comp. fittings

- 300 gallon water storage tank

STANDARD ELECTRICAL CONTROLS:

- 4-line LCD display

- Keypad

- Menu system

- Temperature display

- TDS monitor

- Tank full

- Low pressure

- Hour meter

- Time delay start

- System ON / OFF

- Dual-level control

- Fully-fused

OPTIONS:

- Blending valve

- Throttle valve

- Recycle flow meter

- 20″ BB pre-filter

- 20″ BB post-filter

- 3phase motor w/IEC

- 50hz Motor

- Auto hourly flush

- Feed water TDS monitor

- Pre-treatment lock-out

- Product diversion

- Permeate purge

- Hi-pressure cut-off

| MODEL |

*GPD |

MEMBRANE |

MOTOR |

OPERATING

PRESSURE |

110V-

60HZ

AMPS |

220V-

60HZ- 1hp

AMPS |

RECOVERY

RATE |

PIPING

inlet waste prod |

DIMENSIONS

weight lbs. |

STG-880S

STG-800 |

850+

800+ |

4″x21″

4″x21″ |

.75hp

.75hp |

150psi

200psi |

10.4

10.4 |

5.2

5.2 |

50-60% |

1/2″ 3/8″ 3/8″

FPT FPT FPT |

56″X34″X66″

494 lbs |

STG-1S

STG-1 |

1,800+

1,600+ |

4″x40″

4″x40″ |

.75hp

1.5hp |

150psi

200psi |

11.6

20.0 |

5.8

10.4 |

50-70% |

3/4″ 1/2″ 1/2″

FPT FPT FPT |

56″x34″x66″

750 lbs |

STG-2S

STG-2 |

3,600+

3,170+ |

4″x40″

4″x40″ |

.75hp

1.5hp |

150psi

200psi |

11.6

20.0 |

5.8

10.4 |

50-70% |

3/4″ 1/2″ 1/2″

FPT FPT FPT |

66″x34″x66″

782 lbs |

STG-3S

STG-3 |

5,400+

4,750+ |

4″x40″

4″x40″ |

7.5hp

1.5hp |

150psi

200psi |

11.6

20.0 |

5.8

10.4 |

50-70% |

3/4″ 1/2″ 1/2″

FPT FPT FPT |

66″x34″x66″

810 lbs |

STG-4S

STG-4 |

7,200+

6,340+ |

4″x40″

4″x40″ |

2hp

3hp |

150psi

200psi |

19.2

n/a |

9.8

13 |

50-70% |

3/4″ 1/2″ 1/2″

FPT FPT FPT |

66″x34″x66″

852 lbs |

STG-5S

STG-5 |

9,000+

7,900+ |

4″x40″

4″x40″ |

2hp

3hp |

150psi

200psi |

19.2

n/a |

9.8

13 |

50-70% |

3/4″ 1/2″ 1/2″

FPT FPT FPT |

66″x34″x66″

883 lbs |

STG-6S

STG-6 |

10,800+

9,500+ |

4″x40″

4″x40″ |

2hp

3hp |

150psi

200psi |

19.2

n/a |

9.8

13 |

50-70% |

3/4″ 1/2″ 1/2″

FPT FPT FPT |

66″x34″x66″

910 lbs |

STG-8S

STG-8 |

14,400+

12,670+ |

4″x40″

4″x40″ |

3hp

3hp |

150psi

200psi |

n/a

n/a |

13

13 |

50-70% |

3/4″ 1/2″ 1/2″

FPT FPT FPT |

|

FEED WATER PARAMETERS:

- Temperature: 85° F maximum

- Pressure: 40 – 80 psi maximum

- TDS: 2000-5000 ppm maximum (Consult Dealer for specific model)

- Iron tolerance: 0.5 ppm maximum

- Hydrogen sulfide: must be removed

- Silica tolerance: can not be higher than 100 ppm in the concentrate stream.

(Antiscalant should be considered for any levels over 75 ppm)

- Turbidity: should be removed

- Hardness: must be removed

OPERATING PARAMETERS:

- Operating pressure: 150 – 200 psi maximum

- Water recovery: up to 70% and is field adjusted by customer.

(It is not recommended that the recovery be set higher than 70%)

- pH range: 3 – 11

- Flow rates are determined by the membrane mfg.’s. testing criteria of 1500 ppm Nacl solution, 77°F water temperature, 225 psi at 10-15% recovery. Typical membrane salt rejection is 95-99%

*Actual flow rates may vary depending on the pre-treatment used, water conditions, feed water temperature and applied pressure, etc.

FMV (Frame Mount Vertical)

REVERSE OSMOSIS SYSTEM

Model: MFV (Frame Mount Vertical)

1,600 to 14,400+ GPD

STANDARD FEATURES

- Reverse Osmosis Membrane

- Powder-coated steel frame

- Stainless steel multi-stage pump

- Stainless steel membrane vessel

- High-pressure nylon tubing

- Liquid-filled high pressure gauge

- Inlet/Outlet pre-filter gauges

- Liquid-tight wire shrouding

- Feed water inlet solenoid valve

- Adjstbl. waste & recycle s.s. needle valves

- Product / waste flow meters

- 10″ 5 micron BB pre-filter

- High-pressure brass comp. fittings

STANDARD ELECTRICAL CONTROLS:

- 4-line LCD display

- Keypad

- Menu system

- Temperature display

- TDS monitor with probe

- Tank full

- Low pressure

- Hour meter

- Time delay start

- System ON / OFF

- Dual-level control

- Fully-fused

OPTIONS:

- Nanofiltraion Membrane

(Removes 98% hardness, up to 85% TDS, high recovery rate)

- Blending valve

- Throttle valve

- Recycle flow meter

- 20″ BB pre-filter

- 3phase motor w/IEC

- 50hz Motor

- Auto hourly flush

- Feed water TDS monitor

- Pre-treatment lock-out

- Product diversion

- Permeate purge

- Hi-pressure cut-off

| MODEL |

*GPD |

Feed TDS

2,000

BELOW ABOVE |

Membrane

4″ x 40″QTY |

HP

MOTOR |

Operating

Pressure |

110v-

60hz

amps |

220v-

60hz- 1ph

amps |

Recovery

rate |

PIPING

inlet waste prod |

DEMENSIONS

weight lbs. |

FMV-1S

FMV-1 |

1,800+

1,600+ |

X |

|

1

1 |

.75HP

1.5HP |

150psi

200psi |

11.6

20.0 |

10.4

5.8 |

50-70% |

3/4″ 1/2″ 1/2″

FPT FPT FPT |

24″x29″X53″H

140 lbs |

|

X |

FMV-2S

FMV-2 |

3,600+

3,170+ |

X |

|

2

2 |

.75HP

1.5HP |

150psi

200psi |

11.6

20.0 |

10.4

5.8 |

50-70% |

3/4″ 1/2″ 1/2″

FPT FPT FPT |

30″x30″x53″H

166 lbs |

|

X |

FMV-3S

FMV-3 |

5,400+

4,750+ |

X |

|

3

3 |

.75HP

1.5HP |

150psi

200psi |

11.6

20.0 |

10.4

5.8 |

50-70% |

3/4″ 1/2″ 1/2″

FPT FPT FPT |

30″x30″x53″H

194 lbs |

|

X |

FMV-4S

FMV-4 |

7,200+

6,340+ |

X |

|

4

4 |

2HP

3HP |

150psi

200psi |

19.2

n/a |

9.8

13 |

50-70% |

3/4″ 1/2″ 1/2″

FPT FPT FPT |

30″x30″x56″H

236 lbs |

|

X |

FMV-5S

FMV-5 |

9,000+

7,900+ |

X |

|

5

5 |

2HP

3HP |

150psi

200psi |

19.2

n/a |

9.8

13 |

50-70% |

3/4″ 1/2″ 1/2″

FPT FPT FPT |

30″x30″x56″H

267 lbs |

|

X |

FMV-6S

FMV-6 |

10,800+

9,500+ |

X |

|

6

6 |

2HP

3HP |

150psi

200psi |

19.2

n/a |

9.8

13 |

50-70% |

3/4″ 1/2″ 1/2″

FPT FPT FPT |

30″x30″x56″H

293 lbs |

|

X |

FMV-8S

FMV-8 |

14,400+

12,670+ |

X |

|

8

8 |

3HP

3HP |

150psi

200psi |

n/a

n/a |

13

13 |

50-70% |

3/4″ 1/2″ 1/2″

FPT FPT FPT |

30″x40″x56″H

320 lbs |

|

X |

FEED WATER PARAMETERS:

- Temperature: 85° F maximum

- Pressure: 40 – 80 psi maximum

- TDS: 2000-5000 ppm maximum (Consult Dealer for specific model)

- Iron tolerance: 0.5 ppm maximum

- Hydrogen sulfide: must be removed

- Silica tolerance: can not be higher than 100 ppm in the concentrate stream.

(Antiscalant should be considered for any levels over 75 ppm)

- Turbidity: should be removed

- Hardness: must be removed

OPERATING PARAMETERS:

- Operating pressure: 150 – 200 psi maximum

- Water recovery: up to 70% and is field adjusted by customer.

(It is not recommended that the recovery be set higher than 70%)

- pH range: 3 – 11

- Flow rates are determined by the membrane mfg.’s. testing criteria of 1500 ppm Nacl solution, 77°F water temperature, 225 psi at 10-15% recovery. Typical membrane salt rejection is 95-99%

*Actual flow rates may vary depending on the pre-treatment used, water conditions, feed water temperature and applied pressure, etc.

ECMFV (Economy Frame Mount Vertical)

REVERSE OSMOSIS SYSTEM

Model: ECMFV (Economy Frame Mount Vertical)

1,600 to 14,400+ GPD

STANDARD FEATURES

- Reverse Osmosis Membrane

- Powder-coated steel frame

- Stainless steel multi-stage pump

- Stainless steel membrane vessel

- High-pressure nylon tubing

- Liquid-filled high pressure gauge

- Inlet/Outlet pre-filter gauges

- Liquid-tight wire shrouding

- Feed water inlet solenoid valve

- Adjstbl. waste & recycle s.s. needle valves

- Product / waste flow meters

- 10″ 5 micron BB pre-filter

- High-pressure brass comp. fittings

STANDARD ELECTRICAL CONTROLS:

- Fused OFF / ON safety switch

- Flow switch to protect from low/no feed water pressure

- Float switch for water tank

- 30 amp motor contactor

- 110v-60hz or 220v-60hz

OPTIONS:

- Nanofiltraion Membrane

(Removes 98% hardness, up to 85% TDS, high recovery rate)

- Blending valve +TDS monitor

- Throttle valve

- Recycle flow meter

- Upgrade pre-filter 20″ BB

| MODEL |

*GPD |

Feed TDS

2,000

BELOW ABOVE |

Membrane

4″ x 40″QTY |

HP

MOTOR |

Operating

Pressure |

110v-

60hz

amps |

220v-

60hz- 1ph

amps |

Recovery

rate |

PIPING

inlet waste prod |

DEMENSIONS

weight lbs. |

FMV-1S

FMV-1 |

1,800+

1,600+ |

X |

|

1

1 |

.75HP

1.5HP |

150psi

200psi |

11.6

20.0 |

10.4

5.8 |

50-70% |

3/4″ 1/2″ 1/2″

FPT FPT FPT |

24″x29″X53″H

140 lbs |

|

X |

FMV-2S

FMV-2 |

3,600+

3,170+ |

X |

|

2

2 |

.75HP

1.5HP |

150psi

200psi |

11.6

20.0 |

10.4

5.8 |

50-70% |

3/4″ 1/2″ 1/2″

FPT FPT FPT |

30″x30″x53″H

166 lbs |

|

X |

FMV-3S

FMV-3 |

5,400+

4,750+ |

X |

|

3

3 |

.75HP

1.5HP |

150psi

200psi |

11.6

20.0 |

10.4

5.8 |

50-70% |

3/4″ 1/2″ 1/2″

FPT FPT FPT |

30″x30″x53″H

194 lbs |

|

X |

FMV-4S

FMV-4 |

7,200+

6,340+ |

X |

|

4

4 |

2HP

3HP |

150psi

200psi |

19.2

n/a |

9.8

13 |

50-70% |

3/4″ 1/2″ 1/2″

FPT FPT FPT |

30″x30″x56″H

236 lbs |

|

X |

FMV-5S

FMV-5 |

9,000+

7,900+ |

X |

|

5

5 |

2HP

3HP |

150psi

200psi |

19.2

n/a |

9.8

13 |

50-70% |

3/4″ 1/2″ 1/2″

FPT FPT FPT |

30″x30″x56″H

267 lbs |

|

X |

FMV-6S

FMV-6 |

10,800+

9,500+ |

X |

|

6

6 |

2HP

3HP |

150psi

200psi |

19.2

n/a |

9.8

13 |

50-70% |

3/4″ 1/2″ 1/2″

FPT FPT FPT |

30″x30″x56″H

293 lbs |

|

X |

FMV-8S

FMV-8 |

14,400+

12,670+ |

X |

|

8

8 |

3HP

3HP |

150psi

200psi |

n/a

n/a |

13

13 |

50-70% |

3/4″ 1/2″ 1/2″

FPT FPT FPT |

30″x40″x56″H

320 lbs |

|

X |

FEED WATER PARAMETERS:

- Temperature: 85° F maximum

- Pressure: 40 – 80 psi maximum

- TDS: 2000-5000 ppm maximum (Consult Dealer for specific model)

- Iron tolerance: 0.5 ppm maximum

- Hydrogen sulfide: must be removed

- Silica tolerance: can not be higher than 100 ppm in the concentrate stream.

(Antiscalant should be considered for any levels over 75 ppm)

- Turbidity: should be removed

- Hardness: must be removed

OPERATING PARAMETERS:

- Operating pressure: 150 – 200 psi maximum

- Water recovery: up to 70% and is field adjusted by customer.

(It is not recommended that the recovery be set higher than 70%)

- pH range: 3 – 11

- Flow rates are determined by the membrane mfg.’s. testing criteria of 1500 ppm Nacl solution, 77°F water temperature, 225 psi at 10-15% recovery. Typical membrane salt rejection is 95-99%

*Actual flow rates may vary depending on the pre-treatment used, water conditions, feed water temperature and applied pressure, etc.

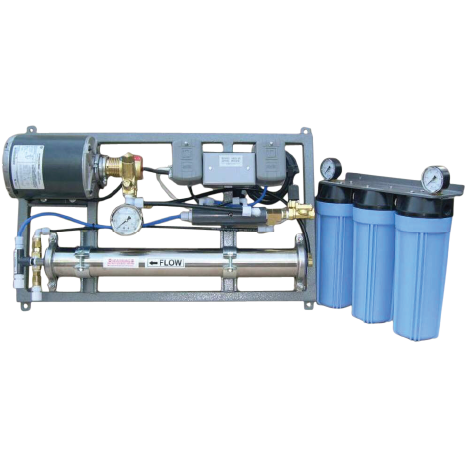

COM (Compact)

Reverse Osmosis System

Model: COM (Compact)

175 to 850+ GPD

STANDARD FEATURES:

- Reverse Osmosis membrane

- Stainless steel membrane vessel

- Powder-coated steel frame

- Liquid-filled system pressure gauge

- Inlet/Outlet pre-filter gauges

- Fixed waste / recycle flow controls, stainless steel

- High-pressure nylon tubing

- High-pressure brass comp. fittings

- Storage tank pressure switch

- Feed water inlet solenoid valve

- Feed water low pressure switch

- Rotary vane pump

- 1/2 to 3/4 hp motor

- 10″ 5 micron sediment pre-filter (1)

- 10″ carbon block pre-filters (2)

- 110 volt – 50/60hz

OPTIONS:

- Nanofiltration membrane

(Rmoves 98% hardness, up 85% TDS, high recovery rate)

- Float switch for atmospheric storage tank

- 220 volt – 50/60hz

| MODEL |

*GPD |

Feed TDS

2,000

BELOW ABOVE |

Membrane

Size |

HP |

110v-

60hz

amps |

220v-

60hz- 1ph

amps |

Recovery

rate |

PIPING

inlet waste prod |

DEMENSIONS

weight lbs. |

COM150S

COM150 |

175+

150+ |

X |

|

2.5″ X 14″

2.5″ X 14″ |

1/2hp

1/2hp |

7.2

7.2 |

3.6

3.6 |

50-60% |

1/2″ 3/8″ 3/8″

FPT FPT FPT |

21″x16″X18″H

53 lbs |

|

X |

COM250S

COM250 |

275+

250+ |

X |

|

2.5″ X 21″

2.5″ X 21″ |

1/2hp

1/2hp |

7.2

7.2 |

3.6

3.6 |

50-60% |

1/2″ 3/8″ 3/8″

FPT FPT FPT |

26″x16″18″H

55 lbs |

|

X |

COM450S

COM450 |

475+

450+ |

X |

|

4″ X 14″

4″ X 14″ |

1/2hp

1/2hp |

7.2

7.2 |

3.6

3.6 |

50-60% |

1/2″ 3/8″ 3/8″

FPT FPT FPT |

21″x16″x18″H

58 lbs |

|

X |

COM800S

COM800 |

850+

850+ |

X |

|

4″ X 21″

4″ X 21″ |

3/4hp

3/4hp |

10.4

10.4 |

3.6

3.6 |

50-60% |

1/2″ 3/8″ 3/8″

FPT FPT FPT |

26″x16″18″H

63 lbs |

|

X |

FEED WATER PARAMETERS:

- Temperature: 85° F maximum

- Pressure: 40 – 80 psi maximum

- TDS: 2000 ppm maximum. If higher, consult factory

- Iron tolerance: 0.5 ppm maximum

- Hydrogen sulfide must be removed

- Silica tolerance can not be higher than 100 ppm in the concentrate stream. Antiscalant should be considered for any levels over 75 ppm

- Turbidity should be removed

- Hardness over 10gpg should be softened

OPERATING PARAMETERS:

- Operating pressure: 200 psi maximum

- Water recovery is factory set at 33 – 35%

- pH range: 3 – 11

- Flow rates are determined by the membrane mfgr’s. testing criteria of 1500 ppm Nacl solution, 77°F water temperature, 225 psi at 10-15% recovery. Typical membrane salt rejection is 95-99%.*Actual flow rates may vary depending on the pre-treatment used, water conditions, system size, membrane array and applied pressure.

COM-II (Compact II)

Reverse Osmosis System

Model: COM-II (compact II)

175 to 850+ GPD

STANDARD FEATURES:

- Reverse Osmosis membrane

- Stainless steel membrane vessel

- Powder-coated steel frame

- Liquid-filled system pressure gauge

- Inlet/Outlet pre-filter gauges

- Fixed waste / recycle flow controls, stainless steel

- High-pressure nylon tubing

- High-pressure brass comp. fittings

- Storage tank pressure switch

- Feed water inlet solenoid valve

- Feed water low pressure switch

- Rotary vane pump

- 1/2 to 3/4 hp motor

- 20″ 5 micron sediment pre-filter (1)

- 20″ carbon block pre-filters (2)

- 110 volt – 50/60hz

OPTIONS:

- Nanofiltration membrane

(Rmoves 98% hardness, up 85% TDS, high recovery rate)

- Float switch for open tank

- Product and Waste Flow Meters

- 220v / 60hz or 220v / 50hz

| MODEL |

*GPD |

Feed TDS

2,000

BELOW ABOVE |

Membrane

Size |

HP |

110v-

60hz

amps |

220v-

60hz- 1ph

amps |

Recovery

rate |

PIPING

inlet waste prod |

DEMENSIONS

weight lbs. |

COM-II-150S

COM-II-150 |

175+

150+ |

X |

|

2.5″ X 14″

2.5″ X 14″ |

1/2hp

1/2hp |

7.2

7.2 |

3.6

3.6 |

50-60% |

1/2″ 3/8″ 3/8″

FPT FPT FPT |

14″x16″X30″H

61 lbs |

|

X |

COM-II-250S

COM-II-250 |

275+

250+ |

X |

|

2.5″ X 21″

2.5″ X 21″ |

1/2hp

1/2hp |

7.2

7.2 |

3.6

3.6 |

50-60% |

1/2″ 3/8″ 3/8″

FPT FPT FPT |

14″x16″30″H

63 lbs |

|

X |

COM-II-450S

COM-II-450 |

475+

450+ |

X |

|

4″ X 14″

4″ X 14″ |

1/2hp

1/2hp |

7.2

7.2 |

3.6

3.6 |

50-60% |

1/2″ 3/8″ 3/8″

FPT FPT FPT |

14″x16″x30″H

66 lbs |

|

X |

COM-II-800S

COM-II-800 |

850+

800+ |

X |

|

4″ X 21″

4″ X 21″ |

3/4hp

3/4hp |

10.4

10.4 |

5.2

5.2 |

50-60% |

1/2″ 3/8″ 3/8″

FPT FPT FPT |

14″x16″x30″H

71 lbs |

|

X |

FEED WATER PARAMETERS:

- Temperature: 85° F maximum

- Pressure: 40 – 80 psi maximum

- TDS: 2000 ppm maximum. If higher, consult factory

- Iron tolerance: 0.5 ppm maximum

- Hydrogen sulfide must be removed

- Silica tolerance can not be higher than 100 ppm in the concentrate stream. Antiscalant should be considered for any levels over 75 ppm

- Turbidity should be removed

- Hardness over 10gpg should be softened

OPERATING PARAMETERS:

- Operating pressure: 200 psi maximum

- Water recovery is factory set at 33 – 35%

- pH range: 3 – 11

- Flow rates are determined by the membrane mfgr’s. testing criteria of 1500 ppm Nacl solution, 77°F water temperature, 225 psi at 10-15% recovery. Typical membrane salt rejection is 95-99%.*Actual flow rates may vary depending on the pre-treatment used, water conditions, system size, membrane array and applied pressure.

COMWM (Compact Wall Mount)

Reverse Osmosis System

Model: COMWM (Compact Wall Mount)

175 to 850+ GPD

STANDARD FEATURES:

- Reverse Osmosis membrane

- Stainless steel membrane vessel

- Powder-coated steel frame

- Liquid-filled system pressure gauge

- Inlet/Outlet pre-filter gauges

- Fixed waste / recycle flow controls, stainless steel

- High-pressure nylon tubing

- High-pressure brass comp. fittings

- Storage tank pressure switch

- Feed water inlet solenoid valve

- Feed water low pressure switch

- Rotary vane pump

- 1/2 to 3/4 hp motor

- 10″ 5 micron sediment pre-filter (1)

- 10″ carbon block pre-filters (2)

- 110 volt – 50/60hz

OPTIONS:

- Nanofiltration membrane

(Rmoves 98% hardness, up 85% TDS, high recovery rate)

- Float switch for open tank

- Wall-Mount Design

- 220v / 60hz or 220v / 50hz

| MODEL |

*GPD |

Feed TDS

2,000

BELOW ABOVE |

Membrane

Size |

HP |

110v-

60hz

amps |

220v-

60hz- 1ph

amps |

Recovery

rate |

PIPING

inlet waste prod |

DEMENSIONS

weight lbs. |

COMWM150S

COMWM150 |

175+

150+ |

X |

|

2.5″ X 14″

2.5″ X 14″ |

1/2hp

1/2hp |

7.2

7.2 |

3.6

3.6 |

50-60% |

1/2″ 3/8″ 3/8″

FPT FPT FPT |

20″H x 30″W x 7″D

53 lbs |

|

X |

COMWM250S

COMWM250 |

275+

250+ |

X |

|

2.5″ X 21″

2.5″ X 21″ |

1/2hp

1/2hp |

7.2

7.2 |

3.6

3.6 |

50-60% |

1/2″ 3/8″ 3/8″

FPT FPT FPT |

20″H x 30″W x 7″D

55 lbs |

|

X |

COMWM450S

COMWM450 |

475+

450+ |

X |

|

4″ X 14″

4″ X 14″ |

1/2hp

1/2hp |

7.2

7.2 |

3.6

3.6 |

50-60% |

1/2″ 3/8″ 3/8″

FPT FPT FPT |

20″H x 30″W x 7″D

58 lbs |

|

X |

COMWM800S

COMWM800 |

850+

800+ |

X |

|

4″ X 21″

4″ X 21″ |

3/4hp

3/4hp |

10.4

10.4 |

5.2

5.2 |

50-60% |

1/2″ 3/8″ 3/8″

FPT FPT FPT |

20″H x 30″W x 7″D

63 lbs |

|

X |

FEED WATER PARAMETERS:

- Temperature: 85° F maximum

- Pressure: 40 – 80 psi maximum

- TDS: 2000 ppm maximum. If higher, consult factory

- Iron tolerance: 0.5 ppm maximum

- Hydrogen sulfide must be removed

- Silica tolerance can not be higher than 100 ppm in the concentrate stream. Antiscalant should be considered for any levels over 75 ppm

- Turbidity should be removed

- Hardness over 10gpg should be softened

OPERATING PARAMETERS:

- Operating pressure: 200 psi maximum

- Water recovery is factory set at 33 – 35%

- pH range: 3 – 11

- Flow rates are determined by the membrane mfgr’s. testing criteria of 1500 ppm Nacl solution, 77°F water temperature, 225 psi at 10-15% recovery. Typical membrane salt rejection is 95-99%.*Actual flow rates may vary depending on the pre-treatment used, water conditions, system size, membrane array and applied pressure.